-

Di-Acro Manual Benders are ruggedly-built, versatile machines for bending wire, solid stock, tubing, flat stock, etc. Accurately forming and duplicating simple, compound, and reverse bends is easy with a Di-Acro Bender. The operator is also able to quickly change over tooling from one bending operation to another. All Di-Acro Benders are identical in operation and operating characteristics - each successive model increases in size and capacity. The fabricating possibilities of Di-Acro Benders are only limited by the ingenuity of the operator. Review the ART OF BENDING to gain insight into the machine’s versatility! MODEL 1 BENDER MANUAL

Di-Acro Manual Benders are ruggedly-built, versatile machines for bending wire, solid stock, tubing, flat stock, etc. Accurately forming and duplicating simple, compound, and reverse bends is easy with a Di-Acro Bender. The operator is also able to quickly change over tooling from one bending operation to another. All Di-Acro Benders are identical in operation and operating characteristics - each successive model increases in size and capacity. The fabricating possibilities of Di-Acro Benders are only limited by the ingenuity of the operator. Review the ART OF BENDING to gain insight into the machine’s versatility! MODEL 1 BENDER MANUAL -

Di-Acro Hand Shears offer precision shearing with burr-free edges. Shear blades offer four (4) cutting edges and can also be sharpened to extend their life. Handle holder may be adjusted to accommodate for operator height and increase leverage when shearing heavier materials. Shearing capacity is 16 gauge mild steel - assuming full shearing width. MODEL 12 HAND SHEAR MANUAL

Di-Acro Hand Shears offer precision shearing with burr-free edges. Shear blades offer four (4) cutting edges and can also be sharpened to extend their life. Handle holder may be adjusted to accommodate for operator height and increase leverage when shearing heavier materials. Shearing capacity is 16 gauge mild steel - assuming full shearing width. MODEL 12 HAND SHEAR MANUAL -

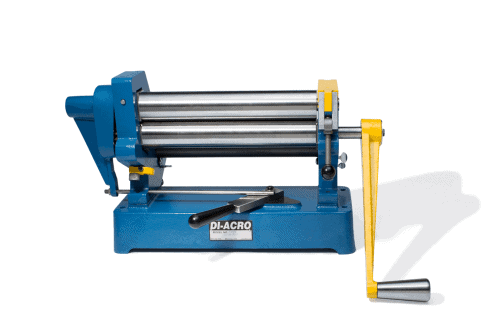

Di-Acro Slip Rollers feature a cam-actuated Idler Roll which permits the forming of circles without flat spots on the leading edge of the material. The operator is also able to locate bends at any point along a sheet of material. Parts can be duplicated with a high-degree of accuracy since the Idler Roll always returns to its pre-set position. Round, flat, and square material can be formed with Di-Acro Rollers by grooving the bending rolls to accommodate the shape of the material. MODEL 12 SLIP ROLLER MANUAL

Di-Acro Slip Rollers feature a cam-actuated Idler Roll which permits the forming of circles without flat spots on the leading edge of the material. The operator is also able to locate bends at any point along a sheet of material. Parts can be duplicated with a high-degree of accuracy since the Idler Roll always returns to its pre-set position. Round, flat, and square material can be formed with Di-Acro Rollers by grooving the bending rolls to accommodate the shape of the material. MODEL 12 SLIP ROLLER MANUAL -

Di-Acro Manual Benders are ruggedly-built, versatile machines for bending wire, solid stock, tubing, flat stock, etc. Accurately forming and duplicating simple, compound, and reverse bends is easy with a Di-Acro Bender. The operator is also able to quickly change over tooling from one bending operation to another. All Di-Acro Benders are identical in operation and operating characteristics - each successive model increases in size and capacity. The fabricating possibilities of Di-Acro Benders are only limited by the ingenuity of the operator. Review the ART OF BENDING to gain insight into the machine’s versatility! MODEL 2 BENDER MANUAL

Di-Acro Manual Benders are ruggedly-built, versatile machines for bending wire, solid stock, tubing, flat stock, etc. Accurately forming and duplicating simple, compound, and reverse bends is easy with a Di-Acro Bender. The operator is also able to quickly change over tooling from one bending operation to another. All Di-Acro Benders are identical in operation and operating characteristics - each successive model increases in size and capacity. The fabricating possibilities of Di-Acro Benders are only limited by the ingenuity of the operator. Review the ART OF BENDING to gain insight into the machine’s versatility! MODEL 2 BENDER MANUAL -

The Model 2 Punch Press is a multi-purpose machine designed to punch holes, of various sizes and shapes, in a wide variety of materials. Di-Acro’s single station punch press is designed with a roller bearing cam action which converts a small amount of operator effort into four (4) tons of punching pressure. Standard holders and adaptors allow the operator to punch from .045” up to 2” in diameter. Optional die holders accommodate punching up to 4” in diameter. Custom tooling is available upon request. MODEL 2 PUNCH PRESS MANUAL

The Model 2 Punch Press is a multi-purpose machine designed to punch holes, of various sizes and shapes, in a wide variety of materials. Di-Acro’s single station punch press is designed with a roller bearing cam action which converts a small amount of operator effort into four (4) tons of punching pressure. Standard holders and adaptors allow the operator to punch from .045” up to 2” in diameter. Optional die holders accommodate punching up to 4” in diameter. Custom tooling is available upon request. MODEL 2 PUNCH PRESS MANUAL -

Di-Acro Rod Parters solve problems in cutting solid bar stock. These precision machines actually "part off" rather than cut, with a combination shearing-breaking action. Parting results in a burr-free edge without further processing or material distortion. Hard materials such as cold-rolled steel and hard aluminum have the best parting results. Dies are reversible for double service. Standard dies have nine round holes ranging from 1/8" to 5/8" in 1/16" increments. All holes are .005" oversized. MODEL 2 ROD PARTER MANUAL

Di-Acro Rod Parters solve problems in cutting solid bar stock. These precision machines actually "part off" rather than cut, with a combination shearing-breaking action. Parting results in a burr-free edge without further processing or material distortion. Hard materials such as cold-rolled steel and hard aluminum have the best parting results. Dies are reversible for double service. Standard dies have nine round holes ranging from 1/8" to 5/8" in 1/16" increments. All holes are .005" oversized. MODEL 2 ROD PARTER MANUAL -

The Di-Acro Tab Notcher provides an efficient means for cutting notches up to 6” x 6” in 16 gauge mild steel sheet metal. Blade adjustment allows tabs up to 1” to be created in one operation. Upper and lower blades are adjustable. Notch any size and depth, regular or tab notch combination, within the capacity of the machine. Overlapping tabs can be easily spot-welded to produce chassis' and boxes with greater strength. MODEL 2 TAB NOTCHER MANUAL

The Di-Acro Tab Notcher provides an efficient means for cutting notches up to 6” x 6” in 16 gauge mild steel sheet metal. Blade adjustment allows tabs up to 1” to be created in one operation. Upper and lower blades are adjustable. Notch any size and depth, regular or tab notch combination, within the capacity of the machine. Overlapping tabs can be easily spot-welded to produce chassis' and boxes with greater strength. MODEL 2 TAB NOTCHER MANUAL -

Finger Brakes are used to form and duplicate boxes, pans, angles, channels, flanges, and "V’s" out of sheet metal - up to 16 gauge mild steel. The operator can easily adjust for material thickness, and use adjustable stops to control bend angle. Box finger segments enable the operator to form boxes from 3/4" up to the full width of the machine in increments as small as 1/4". MODEL 24 FINGER BRAKE MANUAL

Finger Brakes are used to form and duplicate boxes, pans, angles, channels, flanges, and "V’s" out of sheet metal - up to 16 gauge mild steel. The operator can easily adjust for material thickness, and use adjustable stops to control bend angle. Box finger segments enable the operator to form boxes from 3/4" up to the full width of the machine in increments as small as 1/4". MODEL 24 FINGER BRAKE MANUAL -

Di-Acro Hand Shears offer precision shearing with burr-free edges. Shear blades offer four (4) cutting edges and can also be sharpened to extend their life. Handle holder may be adjusted to accommodate for operator height and increase leverage when shearing heavier materials. Shearing capacity is 16 gauge mild steel - assuming full shearing width. MODEL 24 HAND SHEAR MANUAL

Di-Acro Hand Shears offer precision shearing with burr-free edges. Shear blades offer four (4) cutting edges and can also be sharpened to extend their life. Handle holder may be adjusted to accommodate for operator height and increase leverage when shearing heavier materials. Shearing capacity is 16 gauge mild steel - assuming full shearing width. MODEL 24 HAND SHEAR MANUAL -

Di-Acro Slip Rollers feature a cam-actuated Idler Roll which permits the forming of circles without flat spots on the leading edge of the material. The operator is also able to locate bends at any point along a sheet of material. Parts can be duplicated with a high-degree of accuracy since the Idler Roll always returns to its pre-set position. Round, flat, and square material can be formed with Di-Acro Rollers by grooving the bending rolls to accommodate the shape of the material. MODEL 24 SLIP ROLLER MANUAL

Di-Acro Slip Rollers feature a cam-actuated Idler Roll which permits the forming of circles without flat spots on the leading edge of the material. The operator is also able to locate bends at any point along a sheet of material. Parts can be duplicated with a high-degree of accuracy since the Idler Roll always returns to its pre-set position. Round, flat, and square material can be formed with Di-Acro Rollers by grooving the bending rolls to accommodate the shape of the material. MODEL 24 SLIP ROLLER MANUAL